How UV Flashlights Help You Stand Out in the Inspection and Maintenance Industry

You can gain an advantage in the inspection industry by using uv flashlights. These tools help you spot defects and support nondestructive testing. When you switch to uv-LED lamps, you see a 30% drop in chemical exposure incidents and a 45% decrease in chemical waste. UV-LED lamps deliver consistent intensity, reaching 85-95% stability, and last over 10,000 hours. These benefits make your inspection work safer and more reliable.

Key Takeaways

UV flashlights enhance defect detection, revealing flaws that traditional methods miss. This leads to a 95% defect detection rate and faster inspections.

Switching to UV-LED lamps reduces chemical exposure incidents by 30% and chemical waste by 45%, making inspections safer and more efficient.

Using UV flashlights helps meet strict safety and quality standards, giving businesses a competitive edge and attracting clients who value reliability.

Regular use of UV flashlights in inspections can lead to significant cost savings by preventing product failures and reducing repair expenses.

Investing in durable UV flashlights ensures consistent performance in tough environments, lowering maintenance needs and operational costs.

Unique Benefits of UV Flashlights

Enhanced Defect Detection

You improve your inspection results when you use uv flashlights. These inspection tools reveal flaws that escape traditional methods. You spot cracks, leaks, and contamination with greater accuracy. Scientific studies show that uv inspection lamps identify up to 30% more defects than visual inspection alone. You reach a defect detection rate of 95%, while older methods only achieve 75%. You also complete inspections 18% faster on average.

You detect hairline cracks in aircraft landing gear and automotive systems.

You find fluid leaks using uv fluorescent materials.

You identify oil and grease contamination in oxygen vessels and pipework.

Category | Type of Defect | Description |

|---|---|---|

NDT | Crack Detection | Identifies hairline cracks in critical components like aircraft landing gear and automotive systems. |

Leak Detection | Fluid Leaks | Detects leaks in various materials using uv fluorescent materials. |

Contamination | Hydrocarbon Contamination | Identifies oil and grease contamination in oxygen vessels and pipework. |

You use uv flashlights to boost your quality control. You see defects that would otherwise go unnoticed. You reduce the risk of faulty products reaching customers.

Efficiency and Safety

You increase your efficiency with uv flashlights. These inspection tools operate at wavelengths between 365nm and 395nm. You see features that do not appear under normal light. For example, you confirm the authenticity of currency by revealing hidden security features. You finish inspections faster and with fewer errors.

You reduce chemical exposure incidents by switching to uv-LED lamps.

You decrease chemical waste during inspections.

You maintain consistent intensity and reliability in your inspection tools.

Safety remains a top priority. You comply with regulations by assessing uv light exposure levels. You protect workers by providing training and safety measures. You build confidence among your team by managing risks effectively.

Safety Benefit | Description |

|---|---|

Regulatory Compliance | Employers must assess uv light exposure levels and ensure they do not exceed statutory limits, which helps in managing risks effectively. |

Worker Protection | Employees are required to receive training and protective measures, ensuring their safety while using uv light. |

Risk Mitigation | Compliance with regulations builds confidence among workers regarding their safety in the workplace. |

Tip: You should always use proper protective equipment when handling uv flashlights to safeguard your health.

Competitive Edge

You gain a measurable advantage in the inspection and maintenance industry by adopting uv flashlights. You meet strict safety and quality standards, which reduces liability. You benefit from technological advancements that improve inspection accuracy. You save costs because modern uv inspection tools are more affordable. You address industry-specific needs in sectors like aerospace and healthcare, where precise defect detection matters most. You respond to consumer demand for higher quality by investing in advanced inspection technologies.

Factor | Description |

|---|---|

Regulatory compliance | Adoption of uv inspection solutions helps meet strict safety and quality standards, reducing liability. |

Technological advancements | Innovations in uv lights enhance inspection accuracy, encouraging broader adoption in manufacturing. |

Cost-effectiveness | Decreasing costs of uv inspection lights make them accessible for small and medium enterprises. |

Industry-specific needs | Sectors like aerospace and healthcare require precise defect detection, integrating uv lights in QC. |

Consumer demand for quality | Rising awareness drives manufacturers to invest in advanced inspection technologies for competitive edge. |

You position your business as a leader in quality control. You attract clients who value safety, reliability, and innovation. You set yourself apart from competitors by using the latest inspection tools.

UV Technology in Inspection

How UV Works

You rely on uv technology to improve inspection and testing accuracy. The uv-a lamp emits light at a 365nm wavelength, which activates fluorescence in many materials. This process helps you spot defects quickly during testing. The led uv-a lamp uses aluminum-gallium-nitride semiconductors to produce a narrow band of uv light. You benefit from minimal visible light interference, which makes defect detection more precise. The uv-a lamp triggers photoinitiators without stray wavelengths, so you achieve reliable results in adhesive curing and ink testing.

Aspect | Description |

|---|---|

Emission Source | UV-A 365nm wavelength is produced by LEDs designed to emit ultraviolet light. |

Photon Emission | The wavelength is determined by the semiconductor bandgap energy, specifically in aluminum-gallium-nitride (AlGaN) semiconductors. |

Spectral Purity | 365nm UV LEDs emit a narrow band of light, primarily centered around 365 nm, with minimal visible light, making them ideal for industrial applications. |

Activation of Photoinitiators | The UV output effectively activates photoinitiators without introducing stray visible wavelengths, which is crucial for applications like curing adhesives and inks. |

Comparison to Other Sources | Unlike fluorescent UV tubes or mercury lamps that emit broad UV spectra, 365nm LEDs provide a tightly centered emission, enhancing their effectiveness in industrial inspection and avoiding interference with vision systems. |

You use fluorescence inspection to identify cracks, leaks, and contamination. The uv-a lamp reveals flaws that remain hidden under normal lighting. You complete testing faster and with higher sensitivity.

Types of UV Flashlights

You choose from several uv flashlights for inspection and testing. The led uv-a lamp at 365nm suits high-end inspections and forensic testing. You select 385–395nm models for general security and document checks. Some devices above 400nm offer lower sensitivity, so you use them less often in industrial inspection.

Wavelength | Typical Use | Industrial Benefit |

|---|---|---|

365 nm | High-end inspections, forensic use | Strong fluorescence, less visible light interference |

385–395 nm | General security & document checks | Affordable, widely available |

400+ nm | Less common in industry | Lower detection sensitivity |

You match the uv-a lamp type to your inspection needs. The led uv-a lamp provides strong fluorescence for defect detection and testing. You select the right wavelength to maximize inspection accuracy.

Safety in Use

You prioritize safety when using uv flashlights for inspection and testing. You follow strict standards to protect workers from uv exposure. The OStrV and Directive 2006/25/EC require risk assessments and protective measures. DIN EN 62471 ensures that artificial lamps do not harm skin or eyes. You keep exposure below 30 J/m², based on the minimum erythema dose. You recognize that uv-a lamp devices fall into risk groups, with led uv-a lamp models often classified as low risk.

Standard/Directive | Description |

|---|---|

OStrV | Regulates protection from artificial optical radiation, requiring risk assessments and protective measures. |

Directive 2006/25/EC | EU directive for worker protection against artificial optical radiation, including UV. |

DIN EN 62471 | Ensures artificial lamps do not harm skin or eyes, adopting limits from Directive 2006/25/EC. |

You assess risk before starting inspection or testing.

You train workers to use uv-a lamp devices safely.

You provide protective equipment for all inspection tasks.

You monitor exposure levels during testing.

Note: You should always check the classification of your led uv-a lamp and follow manufacturer guidelines to maintain safety during inspection and testing.

Nondestructive Testing Applications

Surface Flaw Detection

You rely on uv flashlights for high-sensitivity ndt in many industries. These tools help you spot surface cracks, scratches, and impurities that traditional inspection methods often miss. When you use uv light, you see flaws that hide under reflections or glossy finishes. This early detection reduces product failure rates by up to 80%. You prevent costly repairs and minimize risks in critical applications such as aerospace, automotive, and oil and gas.

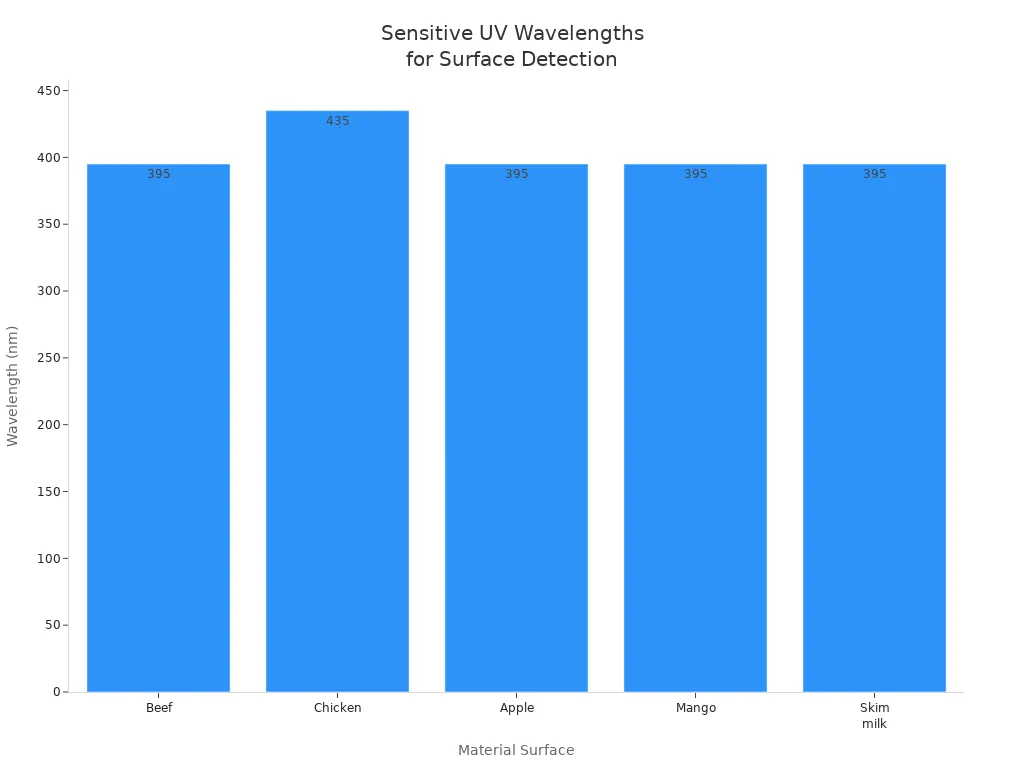

You can see how uv flashlights perform across different material surfaces. The table below shows the most sensitive wavelengths for detecting residues on common surfaces:

Material surfaces | Most sensitive wavelengths (nm) for detecting studied residue |

|---|---|

Beef | 365–445 (395) |

Chicken | 435–490 (435) |

Apple | 395–435 (395) |

Mango | 365–445 (395) |

Skim milk | 365–445 (395) |

You use ndt lamps to identify hidden cracks and imperfections. This process improves your quality control and helps you maintain high standards. You can inspect components in real time and address issues before they become serious problems.

Tip: You should always match the uv wavelength to the surface you inspect for best results.

Quality Control

You strengthen your quality control by using uv flashlights in nondestructive testing. These tools allow you to inspect products without causing damage. You can check for coating coverage, adhesive application, and surface cleanliness. Swedish industry uses uv light to verify conformal coatings by mixing fluorescent substances with glue. Scania ensures truck chassis are fully coated with lacquer using uv inspection. Ericsson uses Labino lamps on production lines to detect non-coated areas in small loudspeaker components.

Industry | Application Description |

|---|---|

Swedish Industry | Uses UV light to check if components are covered by conformal coatings, mixing fluorescent substances with glue. |

Scania | Employs UV light to ensure truck chassis are fully coated with lacquer. |

Ericsson | Utilizes Labino lamps on production lines for small loudspeaker components, detecting non-coated areas with a camera. |

You improve your ndt process by catching defects early. You reduce the risk of faulty products reaching customers. You also meet strict industry standards for inspection and quality control. This approach helps you build trust with clients and maintain your reputation for reliability.

Note: You should document your inspection results to support compliance and traceability.

Cost Savings

You achieve significant cost savings when you use uv flashlights for ndt. Early detection of flaws means you spend less on repairs and replacements. You avoid production delays and reduce waste. You also lower your liability by meeting safety and quality standards. UV inspection helps you minimize chemical use and exposure, which cuts costs related to hazardous materials.

Consider these benefits:

You reduce product failure rates by up to 80% through early flaw detection.

You prevent expensive repairs by identifying cracks and imperfections before they worsen.

You save time and resources by streamlining your inspection process.

You improve overall efficiency in your ndt operations.

You invest in uv technology to support non-destructive testing and quality control. This decision leads to long-term savings and improved business performance.

Callout: You should evaluate your current inspection methods and consider upgrading to uv flashlights for better results and lower costs.

Durability in Industry

Rugged Design

You need inspection tools that can handle tough environments. Modern UV flashlights offer rugged designs built for industrial use. Manufacturers use high wattage ratings to boost UV output, making your inspections more effective. You benefit from rechargeable power sources, such as 18650 lithium-ion batteries, which support frequent use and lower your long-term costs. Safety features like circuit protection for batteries keep your team safe during operation.

High wattage ratings deliver stronger UV light for better defect detection.

Rechargeable batteries provide reliable power and reduce replacement costs.

Circuit protection prevents battery failures and ensures safe operation.

Tip: Choose UV flashlights with reinforced housings and safety certifications for the best performance in demanding settings.

Reliability

You rely on your equipment to work every time, even in harsh conditions. UV flashlights designed for industry use strong materials and advanced engineering to ensure reliability. Aluminum alloy housings protect against drops and impacts. Water resistance, measured by IPX ratings, lets you use your flashlight outdoors or in damp areas. High-quality quartz lenses improve UV transmission and resist scratches better than plastic.

Feature | Description |

|---|---|

Material | Aluminum alloy housings withstand drops and harsh conditions. |

Water resistance | IPX ratings allow use in outdoor or damp environments. |

Lens quality | Quartz lenses improve UV transmission compared to plastic. |

You can trust these flashlights to deliver consistent performance, even when conditions get tough.

Low Maintenance

You save time and money when you use UV flashlights for inspections. These tools require less maintenance than traditional inspection equipment. You experience fewer breakdowns and less downtime, which keeps your operations running smoothly. UV flashlights also help you detect leaks and flaws faster, improving your workflow and reducing costs.

Benefit | UV Flashlights | Traditional Methods |

|---|---|---|

Leak Detection Accuracy Rate | 95%+ | Lower reliability |

Speed of Leak Isolation | 60%+ faster | Slower surveying |

Equipment Downtime Reduction | 80% less | Higher downtime |

Cost Effectiveness | 70% more cost-effective | Higher operational costs |

Note: Regularly check your UV flashlight for battery life and lens cleanliness to maintain top performance.

Industry Use Cases

HVAC and Air Quality

You use uv inspection lamps in the HVAC and air quality market to improve system performance and safety. These lamps help you reduce airborne microorganisms, allergens, and mold spores. You prevent microbial growth on cooling coils and inside ductwork. You also cut down on odors from drainage and other sources. By using uv inspection lamps, you enhance energy efficiency and reduce the need for routine cleaning.

Coil sterilization uv inspection lamps stop mold and bacteria from growing on evaporator coils.

Air sterilization uv inspection lamps sanitize air as it moves through handlers and ducts.

Source | Evidence |

|---|---|

HVAC Surface Treatment using UVC LEDs for Mold Prevention | UVC light prevents the growth of bacteria, mold, and biofilms on HVAC surfaces, enhancing system efficiency and reducing maintenance costs. |

You rely on uv inspection lamps to deactivate airborne molds and mildew. Continuous exposure to UV radiation disrupts the growth cycle of mold spores. This technology helps you maintain a cleaner, healthier environment and gives you a competitive edge in the HVAC market.

Blasting and Painting

You depend on uv inspection lamps to verify surface cleanliness before blasting and painting. These lamps reveal contaminants that you cannot see with the naked eye. Meeting the SP-10 standard requires surfaces to be free of oil, grease, dirt, and other foreign materials. Uv inspection lamps help you meet these strict requirements.

You also use uv inspection lamps to detect hydrocarbons on surfaces. Workers can track in hydrocarbons from storage tanks or shoes. These contaminants can ruin paint adhesion. Uv inspection lamps help you spot these issues quickly.

Tip: Use uv inspection lamps with trace coatings to check for full paint coverage, especially in dimly lit areas.

You improve your quality control and reduce costly rework. This approach strengthens your position in the blasting and painting market.

Manufacturing and Assembly

You use uv inspection lamps to ensure product quality in the manufacturing and assembly market. These lamps help you check for uniform coatings, adhesives, and sealants. You also detect contamination on surfaces and components. Uv inspection lamps allow you to inspect products without causing damage.

You see real-world results in industries like electronics and automotive parts. For example, Swedish manufacturers use uv inspection lamps to verify conformal coatings on truck chassis and loudspeaker components. This process helps you catch defects early and maintain high standards.

Note: Document your inspection results to support compliance and traceability in the market.

Automotive and Aerospace

You rely on uv inspection lamps for defect detection in the automotive and aerospace market. These lamps play a key role in fluorescent penetrant inspection (FPI) and magnetic particle inspection (MPI). You use FPI to find surface defects by applying a fluorescent dye visible under uv inspection lamps. MPI uses magnetic fields and uv inspection lamps to reveal flaws in ferromagnetic materials.

Application | Description |

|---|---|

Fluorescent Penetrant Inspection (FPI) | Used to detect surface defects in materials by applying a fluorescent dye that is visible under UV light. |

Magnetic Particle Inspection (MPI) | Utilizes magnetic fields and UV light to reveal surface and near-surface defects in ferromagnetic materials. |

Quality Control | Monitors uniform coatings, adhesives, sealants, and contamination on surfaces and components. |

You see major improvements in inspection speed and reliability. Aerospace manufacturers use wide-beam, overhead LED uv inspection lamps to boost NDT inspection efficiency. Automotive casting plants increase inspection speed and reduce part handling with these lamps. Uv inspection lamps help you deliver safer, higher-quality products and stand out in a competitive market.

You strengthen your inspection and maintenance operations by choosing UV flashlights. These products deliver consistent intensity, support nondestructive testing, and help you meet industry standards like ASTM E3022 and ISO 3059. You address challenges such as lamp placement, material compatibility, and regular maintenance. The table below highlights how UV flashlights impact your workflow:

Aspect | Description |

|---|---|

Intensity | Focused beams improve inspection of products and reduce errors. |

Longevity | Durable products lower maintenance needs and replacement costs. |

Compliance | Certified products ensure safety and quality in maintenance tasks. |

You see growing demand for these products, driven by technological advancements and regulatory support. By adopting UV flashlights, you expand your product portfolio, improve maintenance efficiency, and position your business for expanding market reach. Remember to maintain your products, keep lenses clean, and follow manufacturer guidelines. This approach ensures your products deliver reliable results, support long-term business growth, and set new standards in maintenance.

FAQ

What makes UV flashlights essential for improving inspection quality?

You use UV flashlights to enhance inspection quality by revealing defects invisible to the naked eye. These tools help you maintain high quality standards in manufacturing, automotive, and aerospace industries. You ensure that every product meets strict quality requirements before reaching customers.

How does fluorescent penetrant testing work with UV flashlights?

You apply fluorescent penetrant testing by coating surfaces with a dye that glows under UV light. You use UV flashlights to spot cracks and flaws during inspection. This method increases your defect detection rate and supports your commitment to quality in critical applications.

Why should you choose fluorescent inspection for quality control?

You select fluorescent inspection to boost your quality control process. You rely on UV flashlights to highlight contamination, coating gaps, and adhesive issues. This approach helps you catch problems early and maintain consistent quality across your production line.

Are UV flashlights safe for regular use in quality inspections?

You protect your team by following safety guidelines when using UV flashlights for quality inspections. You provide training and personal protective equipment. You monitor exposure levels to ensure that your inspection process remains safe while maintaining high quality standards.

Can UV flashlights support quality assurance in multiple industries?

You use UV flashlights to support quality assurance in automotive, aerospace, HVAC, and manufacturing sectors. You rely on these tools for fluorescent penetrant testing and fluorescent inspection. You improve your inspection accuracy and maintain quality across diverse applications.

See Also

Exploring UV Flashlights: Their Uses and Advantages

Different UV Flashlight Varieties Commonly Found in Forensics

Advantages of Rechargeable Flashlights for Community Safety

Hunting Flashlights: Key Gear for Outdoor Adventure Lovers

Designed for Longevity: The Sturdiness of Our Emergency Flashlight