How MOQ impacts flashlight pricing and cost optimization for flashlights in bulk

You face unique challenges when sourcing wholesale flashlights. Minimum order quantity plays a critical role in shaping pricing and overall profit. If you order larger batches, labor efficiency often improves, which can enhance profit margins. However, high minimum order quantity can increase holding costs and affect cash flow. The table below shows how key factors influence profit margins for bulk flashlight purchases:

Factor | Impact on Profit Margins |

|---|---|

Labor Efficiency | Larger batch sizes can improve profit margins. |

Inventory Turns | Higher inventory turns boost profitability; excess stock reduces turns. |

Holding Costs | High holding costs reduce profit margins, especially with high minimum order quantity. |

Break-even Point | Identifying break-even points helps determine minimum quantity for profitability. |

Demand Forecasting | Accurate forecasting prevents excess inventory, protecting profit. |

Supplier MOQs | Supplier-imposed moq affects cash flow and profit. |

If you want to maximize savings, consider both pricing and operational impacts before placing your next bulk flashlight order.

Key Takeaways

Understand Minimum Order Quantity (MOQ) to plan your inventory and budget effectively. Check supplier requirements before negotiations.

Negotiate MOQ with suppliers to unlock cost savings. Build strong relationships and communicate your needs clearly for better terms.

Leverage bulk discounts by ordering larger quantities. This strategy reduces per-unit costs and improves profit margins.

Monitor your inventory closely to avoid overstocking. Use demand forecasting tools to align orders with actual needs.

Consider group buying with other businesses to meet MOQ requirements. This approach helps you access better pricing and share costs.

MOQ in Wholesale Flashlights

What Is Minimum Order Quantity?

You often see the term minimum order quantity when you research wholesale flashlights. This term refers to the smallest number of units a supplier will accept in a single order. Suppliers set this threshold to ensure that production and logistics remain cost-effective. You might encounter different minimum order quantity requirements based on the complexity of the flashlight design or the supplier’s capabilities.

For simple modifications, some manufacturers set the minimum order quantity as low as 100 units.

If you request a new mold or a custom design, the minimum order quantity can exceed 1,000 units.

Certain suppliers, such as Shenzhen Xiaobu Smart Technology Co., Ltd., offer ultra-low minimum order quantity options. These options help startups and small brands enter the market without a large upfront investment.

You should always check the minimum order quantity before you start negotiations. This step helps you plan your inventory and budget more accurately.

Why MOQ Matters for Wholesale Flashlights

The minimum order quantity directly impacts your purchasing strategy. When you buy wholesale flashlights, you must balance your need for inventory with your available cash flow. If you order a large quantity, you may secure a lower unit price, but you also risk tying up funds in unsold stock.

Chinese manufacturers usually require a higher minimum order quantity, often between 500 and 5,000 units per SKU. Their large-scale production allows them to offer competitive pricing, but you must commit to a bigger quantity. Indian suppliers, on the other hand, tend to accept lower minimum order quantity levels, sometimes between 100 and 1,000 units per SKU. This flexibility benefits smaller businesses and those who want to test new products.

Tip: Always compare minimum order quantity policies from different suppliers. This approach helps you find the right balance between price, quantity, and flexibility.

When you understand how minimum order quantity works, you can make smarter decisions about your inventory and costs.

MOQ and Flashlight Pricing

MOQ’s Impact on Unit Price

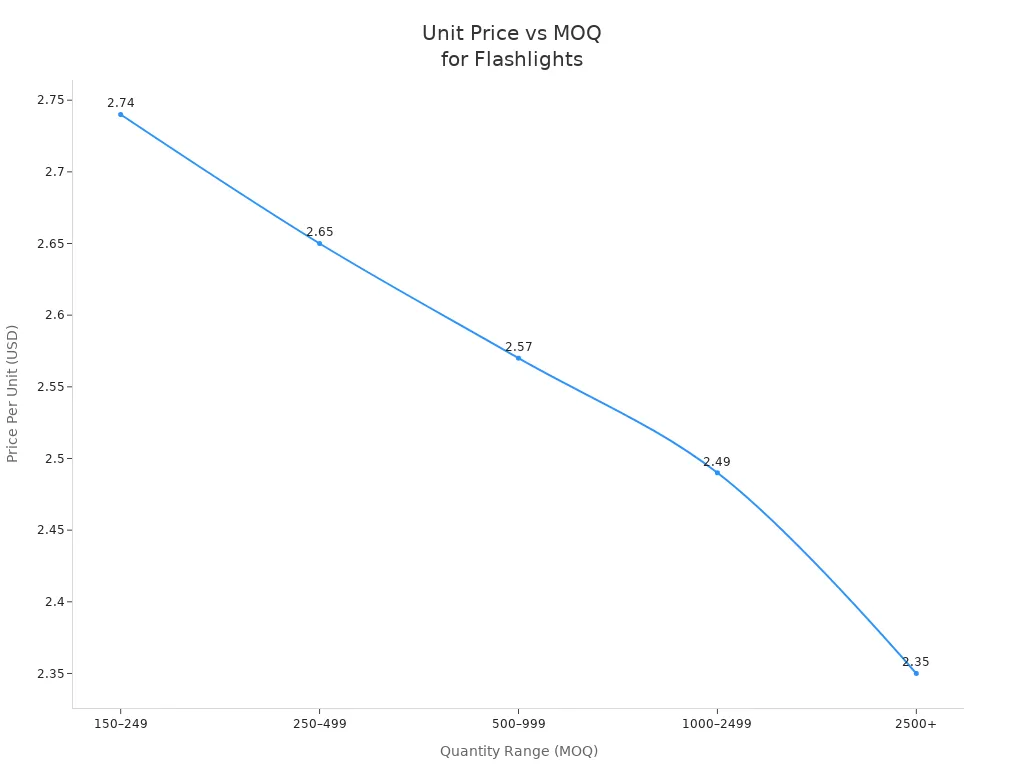

You can see a direct link between minimum order quantity and unit price when you source wholesale flashlights. Suppliers often offer lower prices as you increase your quantity. This pricing structure rewards you for larger commitments. The table below shows how unit price drops as your order quantity rises:

Quantity Range | Price Per Unit (USD) |

|---|---|

150 – 249 | $2.74 |

250 – 499 | $2.65 |

500 – 999 | $2.57 |

1000 – 2499 | $2.49 |

2500+ | $2.35 |

You benefit from lower unit costs when you meet higher minimum order quantity thresholds. This approach helps you optimize your pricing and improve your profit margins. If you order below the supplier’s moq, you may face higher prices or extra fees.

Tip: Always ask suppliers for a breakdown of unit price at different quantity tiers. This information helps you plan your budget and maximize savings.

Economies of Scale in Flashlight Orders

When you increase your order quantity, you unlock economies of scale. Suppliers can produce flashlights more efficiently in larger batches. You save on per-unit production costs and often qualify for better shipping rates. The table below highlights the advantages of bulk purchasing:

Evidence Type | Description |

|---|---|

Bulk Price Savings | Businesses that buy in bulk save an average of 27%. Some products offer savings up to 63%. |

Reduced Shipping Costs | Large orders often qualify for reduced shipping rates. Consolidating shipments lowers handling fees. |

You can see significant savings when you consolidate your orders. Suppliers may offer special pricing for orders above certain quantity thresholds. For example, if you order 1,000 units, you might pay $8.00 per flashlight. If you increase your quantity to 5,000 or more, the price drops to $6.50 per unit.

MOQ (Units) | Unit Price ($) |

|---|---|

1,000 | 8.00 |

5,000+ | 6.50 |

You should consider your storage capacity and demand forecasts before committing to a large quantity. This strategy helps you avoid overstock and hidden costs.

Manufacturing Complexity and MOQ

Manufacturing complexity plays a major role in setting minimum order quantity for flashlights. If you choose a design with many components or custom features, suppliers may require a higher moq. The table below outlines common factors that influence moq requirements:

Factor | Description |

|---|---|

Size of the Bill of Materials | A larger BOM with many components requires more time to manage, affecting minimum order quantity. |

Effort to Assemble | Complex assembly processes need more planning and resources, leading to higher moq. |

Amount of Testing Required | Extensive testing ensures quality but increases time and resources, raising moq. |

Complexity of Packaging | Intricate packaging needs more resources and planning, which can increase moq. |

If you request custom features such as higher brightness or longer beam distance, suppliers may set the minimum order quantity at 500 units or more. Smaller orders often come with extra fees for packaging printing or special materials.

Customization options like brightness and beam distance can change your costs.

Minimum order quantity for custom flashlights is usually 500 units.

Small quantity orders may include extra charges for packaging printing.

You should discuss your design and packaging needs with suppliers before finalizing your order. This step helps you understand how manufacturing complexity affects moq and pricing.

Optimizing MOQ for Cost Savings

Negotiating MOQ with Suppliers

You can unlock significant cost savings by negotiating minimum order quantity with your suppliers. Optimizing moq starts with understanding your supplier’s needs and building a strong relationship. Regular communication helps you learn about their production challenges and opens the door to more favorable terms. You may offer to pay a slightly higher price per unit, which can compensate for the supplier’s reduced profitability on smaller orders. This approach demonstrates your commitment and can lead to a lower minimum order quantity.

A trial order often works well. You propose a smaller initial quantity to show your potential as a long-term partner. Suppliers may agree to this if you present market data that supports future demand for wholesale flashlights. Exploring alternative production techniques also helps in optimizing moq, as suppliers may find more efficient ways to fulfill your order.

Build a strong relationship with your supplier through regular communication.

Offer a higher price per unit to offset reduced profit for the supplier.

Propose a trial order to demonstrate your business potential.

Present market data to support your request for a lower minimum order quantity.

Discuss alternative production methods to reduce moq.

A boutique skincare brand negotiated a 200-unit minimum order quantity by offering a slightly higher per-unit price and committing to increase orders over time. You can use similar strategies to optimize moq and reduce your upfront cost.

Leveraging Volume Discounts

You benefit from bulk discounts when you purchase larger quantities of flashlights. Suppliers reward you with lower per-unit costs because they achieve greater efficiency in production and shipping. Optimizing moq allows you to access exclusive discounts and reduce your overall cost. You also save on packaging and handling expenses, as fewer shipments mean lower transportation fees.

Bulk buying leads to significant savings through volume discounts.

Lower per-unit cost results from efficient production and shipping.

Reduced packaging and handling expenses help you control cost.

Fewer shipments lower transportation fees.

Suppliers offer exclusive discounts for large purchases.

The table below shows how optimizing moq and leveraging bulk discounts can impact your profit and cost structure:

Quantity Ordered | Per-Unit Cost | Total Cost | Bulk Discount | Profit Margin |

|---|---|---|---|---|

200 | $2.80 | $560 | None | Lower |

1,000 | $2.50 | $2,500 | Yes | Higher |

5,000 | $2.30 | $11,500 | Yes | Highest |

You should analyze your demand forecasts and storage capacity before committing to a large quantity. This step ensures you optimize moq without risking excess inventory or cash flow issues.

Group Buying and Collaboration

You can further reduce cost and optimize moq by joining group buying initiatives or collaborating with other businesses. When you pool your orders with others, you reach the supplier’s minimum order quantity more easily and unlock bulk discounts. This strategy helps you access better pricing and share the benefits of lower cost with your partners.

Group buying allows you to meet minimum order quantity requirements.

Collaboration helps you access bulk discounts and lower per-unit cost.

Shared orders reduce the risk of overstock and improve cash flow.

You gain negotiating power with suppliers for better pricing.

Optimizing moq through group buying balances your inventory needs and cash flow. You avoid tying up too much capital in unsold stock and maximize your profit. This approach works well for small businesses and startups that want to enter the market without a large upfront investment.

Tip: Always communicate clearly with your partners and suppliers when organizing group purchases. Transparency ensures everyone benefits from optimized moq and reduced cost.

By focusing on optimizing moq through negotiation, volume discounts, and collaboration, you create a more efficient purchasing strategy for wholesale flashlights. You balance your inventory, control your cost, and improve your profit margins.

Managing Inventory and Cash Flow

Assessing Inventory Needs

You must evaluate your inventory needs before placing bulk flashlight orders. Accurate inventory management helps you avoid shortages and excess stock. You can use several methods to track inventory and maintain optimal levels. The table below outlines common approaches:

Method | Description | Best For |

|---|---|---|

Periodic Inventory Counts | Counts inventory at set intervals (monthly, quarterly, annually). | Smaller businesses with low inventory |

Perpetual Inventory Counts | Real-time tracking that updates inventory levels with each transaction. | Businesses needing up-to-date info |

Cycle Counting | Regularly counts a portion of inventory on a rotating basis. | Ensuring accuracy over time |

Ad-Hoc Counting | Unschedulled counts for suspected discrepancies. | Quick checks in specific areas |

Inventory forecasting tools also support inventory management by analyzing sales data and recommending purchase quantities. These tools help you align orders with demand and minimum order quantity requirements. You gain visibility into supplier restrictions and inventory levels, which improves decision-making.

Cash Flow Strategies for MOQ Orders

Managing cash flow is essential when dealing with large minimum order quantity commitments. You can use several strategies to maintain healthy cash flow and support inventory management:

Negotiate payment terms with suppliers to spread out costs.

Request inventory in installments to avoid tying up funds.

Use demand forecasting and inventory planning tools to determine optimal purchase volumes.

Implement just-in-time inventory systems to reduce storage costs.

Ask for payment plans to ease cash flow pressures.

You should also consider negotiating lower moq with suppliers. This approach improves profitability and helps you manage inventory more effectively.

Tip: Effective inventory management prevents overstocking and reduces unnecessary expenses.

Avoiding Overstock and Hidden Costs

Overstocking flashlights due to high minimum order quantity can lead to hidden costs. You must monitor inventory closely and use strategic ordering to minimize waste. The table below highlights common hidden costs:

Cost Type | Description |

|---|---|

Initial Purchase Price | The upfront cost of buying multiple flashlights due to high MOQ, which can add up significantly. |

Storage Costs | Additional expenses incurred for storing excess flashlights that are not in use. |

Shipping Costs | Costs associated with shipping multiple units, which can increase with higher quantities. |

Redundancy in Products | Having multiple flashlights that serve similar purposes, leading to wasted resources. |

Compatibility Issues | Different flashlights may not be cross-compatible, leading to additional costs when replacements are needed. |

You can avoid overstock by forecasting demand accurately and collaborating with suppliers. Place smaller orders for non-essential items and use direct shipping options to reduce inventory holding. Conduct regular inventory counts and leverage inventory management software to track turnover and sell-through rates.

Note: Strategic inventory management helps you minimize waste and maximize profit.

Shipping and Logistics in Bulk Orders

Reducing Shipping Costs with Bulk Flashlights

You can lower shipping expenses by choosing the right strategies for bulk flashlight orders. Sea freight works well for large shipments because it offers better rates than air or express options. You should optimize packaging to reduce weight and volume. This step helps you avoid extra charges and makes handling easier. Consolidating shipments allows you to fill cargo space efficiently. You may see up to 20% savings per truckload when you combine orders. Negotiating shipping rates with suppliers gives you access to discounted prices. These actions help you control your overall cost and keep your business competitive.

Select sea freight for bulk orders to maximize savings.

Use packaging that minimizes weight and volume.

Consolidate shipments to reduce costs.

Negotiate rates with suppliers for better deals.

Tip: Always review your shipping options before finalizing your order. Small changes in packaging or shipment size can make a big difference in your bottom line.

Distributing Fixed Costs Across Orders

You can spread fixed costs over multiple units when you order flashlights in bulk. This approach lowers the cost per item and improves your profit margin. Fixed costs include shipping fees, customs charges, and handling expenses. When you meet the supplier’s moq, you distribute these costs more effectively. The table below shows how fixed costs impact unit pricing:

Total Fixed Cost | Units Ordered | Fixed Cost Per Unit |

|---|---|---|

$500 | 500 | $1.00 |

$500 | 1,000 | $0.50 |

$500 | 2,000 | $0.25 |

You should plan your orders to maximize the number of units per shipment. This strategy helps you achieve better pricing and reduces the impact of fixed costs on your business. You gain more control over your expenses and improve your ability to compete in the market.

Note: Efficient logistics planning supports cost optimization and helps you manage your resources wisely.

Building Supplier Relationships

Communicating MOQ Needs

You gain a competitive edge when you build strong relationships with your suppliers. Open and honest communication about your minimum order quantity needs helps you achieve better negotiation outcomes. When you share your business goals and order forecasts, you foster trust. This trust leads to transparent pricing and more flexible terms. Suppliers often reward clear communication with improved pricing, better discount structures, and even exclusive offers.

Strong supplier relationships help you negotiate more favorable terms.

Open communication builds trust and supports transparent pricing.

Healthy relationships can unlock better discounts and exclusive deals.

Tip: Schedule regular check-ins with your suppliers. Use these meetings to discuss your upcoming needs and any changes in your business. This approach keeps both sides aligned and ready to adapt.

Long-Term Partnerships for Better Terms

You benefit from long-term partnerships with your suppliers. These relationships often lead to better products, improved deals, and enhanced business performance. When you involve suppliers early in your design process, you can use their expertise to secure better minimum order quantity terms. Ongoing partnerships also make it easier to negotiate structured pricing and cost reductions.

Benefit | Description |

|---|---|

Improved Supplier Relationships | Suppliers prioritize you, offering better service and more favorable terms. |

Cost Reduction | Bulk purchasing and negotiated terms lower your prices. |

Predictable Pricing | Structured pricing strategies create stability for both you and your supplier. |

Bulk pricing does more than provide discounts. It strengthens your relationship with suppliers and increases the value of your orders. Predictable revenue from ongoing orders encourages suppliers to offer you better terms and consistent pricing.

Bulk pricing increases order value and strengthens supplier relationships.

Structured pricing brings predictability to your costs and revenue.

Long-term partnerships help you optimize your purchasing strategy.

Note: Investing in supplier relationships pays off over time. You gain flexibility, better pricing, and reliable support for your business growth.

You now see how minimum order quantity shapes pricing, cost, and profit when sourcing wholesale flashlights. Strategic management of moq lets you boost profit and avoid excess inventory. Strong supplier relationships help you negotiate better minimum order quantity terms. Apply these strategies to improve your inventory control and maximize profit. Next, review your supplier agreements and forecast demand before placing your next order.

Take action today to optimize your purchasing and secure better results.

FAQ

What does MOQ mean in flashlight sourcing?

MOQ stands for Minimum Order Quantity. You must order at least this number of units from a supplier. This requirement helps suppliers manage production costs and efficiency.

How can you negotiate a lower MOQ with suppliers?

You can negotiate by showing your long-term business potential. Offer to pay a slightly higher unit price or propose a trial order. Suppliers often respond positively to clear communication and future order commitments.

Does a higher MOQ always mean lower unit prices?

Usually, yes. Suppliers often reduce the unit price when you order more flashlights. This discount reflects their lower production and shipping costs per unit at higher volumes.

What risks do you face with high MOQ orders?

You risk overstocking and tying up cash in unsold inventory. You may also face higher storage costs. Accurate demand forecasting and inventory management help you avoid these issues.

See Also

Selecting The Ideal High-Intensity Flashlight For Your Needs

Exploring The Benefits Of Continuous Dimming In Flashlights

Key Guidelines For Proper Care Of Your Flashlight

Finding The Best Everyday Carry Flashlight For Holiday Gifts