Industrial Use Flashlights: Essential Tools for Maintenance, Inspection, and Repair Teams

You face many dangers when you work in factories. Good lighting keeps you safe. It also helps you work faster. Bad lighting causes 25% of work accident claims. Good lighting stops up to 60% of work accidents. It can also make people work 20% faster.

Statistic | Impact |

|---|---|

Bad lighting causes 25% of work accident claims | Shows why good lighting is needed to stop accidents |

Good lighting stops up to 60% of work accidents | Shows how lighting helps keep people safe |

Good lighting can make people work 20% faster | Shows how lighting helps people work better |

You need a flashlight that works in dark and risky places. Special flashlights like intrinsically safe models, LED units, and penlights help keep you safe. The helius flashlight helps you see well and find dangers fast. Good lighting keeps you safe, helps you not slip, and lets you check equipment closely.

Key Takeaways

Good lighting helps stop work accidents by 60%. Use good flashlights to stay safe in dark places. These places can be risky for workers.

Pick intrinsically safe flashlights for dangerous areas. These flashlights stop sparks from happening. They keep you safe in oil, gas, or mining jobs.

Get flashlights with high lumens for better sight. Try to use at least 1000 lumens. This helps you see small things and spot dangers.

Hands-free flashlights like headlamps help you work better. Magnetic flashlights also let you use both hands. You can work safely and faster.

Check your flashlights often and take care of them. Make sure they are charged and ready for emergencies. This helps you stay safe and work well.

Essential Tools for Maintenance

Safety Benefits

You work in places where safety matters most. Good lighting helps you stay safe. It lets you see dangers before they hurt you. Intrinsically safe lights protect you in risky areas. These lights do not make sparks. You can use them in oil, gas, or mining jobs.

Good lighting helps your eyes feel less tired. You make fewer mistakes when you are not tired. You can see spills, wires, or sharp things better. You can avoid slipping or falling because you see the floor and your way.

Safety Incident | Prevention Method |

|---|---|

Slips, trips, and falls | |

Eye strain and fatigue | Task lighting keeps your eyes comfortable |

Misidentification of hazards | Bright light helps you spot dangers |

You need tools that give even light everywhere. Shadows can hide dangers, so even light is important. Task lighting helps you see small parts or tight spots. Emergency lights help you get out safely if the power goes off. Using these tools helps you avoid accidents during maintenance.

Good lighting keeps your eyes from getting tired.

Task lighting helps you work on small things safely.

Seeing clearly helps you find dangers and stay safe.

Efficiency and Accuracy

Essential tools help you work faster and better. The right lighting lets you see every detail. You can find worn parts, leaks, or cracks early. This helps you fix problems before they get worse.

Feature | Benefit |

|---|---|

Reliable Illumination | Helps you work well in dark places and stay safe. |

Multiple Lighting Modes | Lets you pick the best light for each job. |

Rechargeable Batteries | You can charge them fast and keep working. |

Durable Construction | Strong lights work well in tough places. |

Advanced Features | Extra features make work safer and more comfortable. |

You need tools that give bright and steady light. High-lumen lights show all parts of equipment. You can adjust the beam to see small spots or big areas. This helps you find problems fast and fix them quickly.

Good lighting helps you see dangers and do your job right.

Enough light helps you make fewer mistakes during work.

In factories and construction, good lighting helps you check materials and products.

Studies show that better lighting helps people do tasks more accurately.

Research says more daylight helps people learn and work better, which helps with maintenance and inspection.

You use essential tools to finish jobs on time. Seeing clearly helps you make fewer mistakes. You spend less time fixing errors. This means you finish faster and keep machines working well. A good flashlight is one of the most important tools for these jobs.

Flashlight Features

Durability

You need a tool that can handle hard work. Industrial flashlights last in tough places. Makers use strong materials like aluminum, stainless steel, titanium, and composite. These materials help the flashlight fight damage and rust. They also protect it from bumps and drops. Intrinsically safe models work in very hot or cold places. They do not break easily if hit.

Material | Properties and Advantages |

|---|---|

Aluminum | Lightweight, strong, fights rust, and spreads heat well. |

Stainless Steel | Very strong, good for heavy jobs, does not bend easily. |

Titanium | Strong but light, fights rust, and lasts long. |

Composite | Light, tough, fights rust, used for special jobs. |

Tip: Pick a flashlight with sealed parts and shock protection. This helps it survive falls, dust, and water.

Flashlights work in very hot or wet places.

Strong bodies protect them from bumps and drops.

Factories have dust, chemicals, heat, water, shaking, and power changes. Tough flashlights keep dust out and use materials that fight chemicals. They have sealed bodies to keep water out. They work in hot places and can handle shaking from big machines. Surge protection helps them work when power changes fast.

Dust can make flashlights too hot, but tough ones keep dust out.

Chemical fumes can hurt parts, so industrial flashlights use special seals.

Heat and water can break normal lights, but industrial ones fight these problems.

Shaking from machines can break lights, but tough ones are tested for this.

Dangerous places need certified flashlights for safety.

Brightness

You need bright light to see small things and find problems. Most industrial flashlights give 500 or more lumens. For checking and fixing things, 1000 lumens is best. Quality control teams use flashlights with at least 1000 lumens. This helps them see tiny bits and water drops.

Flashlights with 500+ lumens work for many jobs.

For checking things, 1000 lumens helps you see better.

Quality teams like flashlights with 1000 lumens or more.

You can change the brightness for different places. Use low light in small spaces. Use bright light in big areas. This keeps your eyes feeling good and helps you make fewer mistakes.

Benefit Type | Description |

|---|---|

Improved Visibility | Lets you see well in bright or dark places. |

Reduced Errors | Makes things easy to read, so you mess up less. |

Enhanced User Experience | Auto brightness keeps your eyes from hurting. |

Increased Safety | Bright light shows warnings, so you can act fast. |

Boosted Efficiency | Clear light helps you work faster and better. |

Note: The right brightness helps you see danger and act fast.

Hands-Free Options

You often need both hands to do your job. Hands-free flashlights help you stay safe and work faster. Headlamps let you move and keep your hands on tools. Magnetic bases stick to metal, so you can point the light where you need it. Clips and straps help you put the light in different places.

Feature | Advantage |

|---|---|

Magnetic Base | Sticks to metal for hands-free use |

Clips/Head Straps | Lets you put the light where you want |

Durability | Lasts long in tough places |

Waterproofing | Keeps water out |

Headlamps give you light while you climb or carry tools.

You can point the beam for better sight and safety.

Flashlights with beams you can change help with careful jobs.

Rechargeable flashlights work as backup for night or emergencies.

Tip: Hands-free flashlights help you avoid accidents and finish work faster.

Battery Life

You need a flashlight that works as long as you do. Industrial flashlights use lithium-ion batteries. These batteries last 6 to 24 hours per charge. How long they last depends on how bright you set the light. You should plan your work so your flashlight does not run out of power.

Checking and fixing things often helps you find problems early and stop delays.

Battery Type | Voltage (V) | Capacity (mAh) Range | Common Sizes |

|---|---|---|---|

NiMH | 1.2 | AA: 800-2800, AAA: 1000-1500, C: 3000-5000, D: 6000-10000 | AA, AAA, C, D |

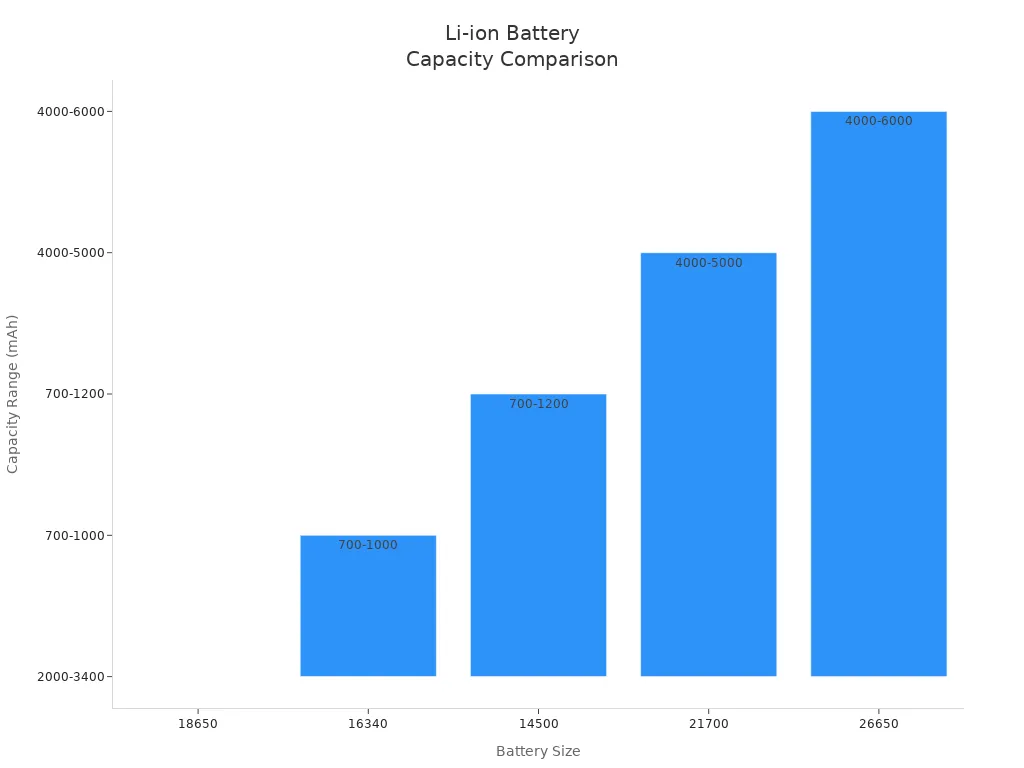

Li-ion | 3.7 | 18650: 2000-3400, 16340: 700-1000, 14500: 700-1200, 21700: 4000-5000, 26650: 4000-6000 | 18650, 16340, 14500, 21700, 26650 |

Note: Rechargeable batteries save money and help you buy fewer new batteries.

Types of Industrial Flashlights

LED Flashlights

You use LED flashlights for many factory jobs. These lights are bright and last a long time. They use less power than old flashlights. This saves you energy and money. LED flashlights work well in tough places. They do not break from bumps or heat. The table below shows how they are different from halogen flashlights:

Feature | LED Flashlights | Halogen Flashlights |

|---|---|---|

Brightness and Light Output | Very bright, up to 2000+ lumens | Bright at first, but gets dimmer over time |

Energy Efficiency | Uses less power, lasts much longer | Uses more power, batteries run out fast |

Durability | Lasts 25,000-50,000 hours, very strong | Does not last long, breaks easier |

Heat Emission | Stays cool, safe to touch | Gets hot, can burn you |

Cost Considerations | Costs more at first, but saves money later | Cheaper at first, but costs more over time |

Environmental Impact | Good for the planet, low carbon footprint | Not as good for the planet |

LED flashlights let you work longer without new batteries.

You get strong light for checking machines or dark places.

Good LED flashlights help you do better work and save money.

Tip: Pick LED flashlights to save energy and use them longer at work.

Intrinsically Safe Flashlights

You need intrinsically safe flashlights near flammable gas or dust. These lights keep you safe by stopping sparks and heat. You see them in oil, gas, and chemical plants. They use special circuits and controls to stop fires.

Step | Description |

|---|---|

Design and Engineering | Made to stop fires from starting. |

Testing | Tested in hot, cold, and dangerous places. |

Documentation | Has papers and reports to show it is safe. |

Inspection | Checked by experts to make sure it is safe. |

Certification | Gets a safety certificate for risky places. |

Intrinsically safe flashlights work in Class 2 Division 1 zones.

You use them in mining, oil, and chemical work.

These flashlights stay cool and do not make sparks.

Note: Always check for safety certificates before using a flashlight in risky places.

Penlights and Inspection Lights

You use penlights and inspection lights for small spaces. These tools help you find problems where big flashlights cannot fit. You can check machines, wires, or pipes easily.

Penlights help you check drums with flammable vapor.

Inspection lights let you see inside tight spaces.

You find problems early and fix them before they get worse.

Bright tips and angled heads help you see every detail.

Tip: Keep a penlight in your pocket for quick checks and repairs.

Headlamps

You need headlamps when you want both hands free. Headlamps shine light wherever you look. This makes it easier to work on machines or climb ladders. They help you not trip or fall in dark places.

Advantage | Description |

|---|---|

Preventing Trips and Falls | Gives you light to see where you walk. |

Enhanced Focus and Task Accuracy | Adjustable brightness helps you do your job right. |

Quicker Response Times | Fast lighting helps in emergencies. |

Hands-Free Operation | Lets you use both hands for work. |

Better Communication | Workers use light signals to talk without words. |

Headlamps help you stay safe and work better with your hands.

You get good light for fixing things in dark places.

Strong headlamps help you finish jobs faster.

Note: Headlamps are important for working safely in small or dark spaces.

Real-World Applications

Confined Spaces

You sometimes work in small places like tanks or tunnels. These spots are hard to get into. You cannot bring big lights inside. You face problems like:

Only a few ways in or out

Not much fresh air

Lots of shadows and it is hard to see

Needing both hands for your tools

Very strict safety rules

Special flashlights help you with these problems. Intrinsically safe models stop sparks, so you stay safe near gas or dust. Small flashlights fit in tight spaces. Headlamps and penlights let you move and use your hands. You can check these areas and not miss hidden dangers.

Tip: Always look at your flashlight’s safety rating before you go into a small space.

Emergency Situations

The power can go out or machines can break anytime. You need a good flashlight to help you see in the dark. Flashlights give you extra light so you can move safely. They help you not get hurt. Long battery life and strong bodies mean your flashlight works when you need it. Rechargeable and solar-powered flashlights help you be ready for any emergency.

Maintenance teams teach workers how to use flashlights fast. You practice drills to find and use flashlights. You also keep flashlights near doors and emergency spots. This helps you act fast and stay safe when there is a real emergency.

Note: Practicing with your flashlight during drills helps you move quickly when the lights go out.

Equipment Inspection

You use flashlights every day to check equipment. Good lighting helps you find leaks, cracks, or worn parts. You can look in dark corners or behind panels. Bright, focused beams help you see small things that ceiling lights miss.

Task | How Flashlights Help |

|---|---|

Checking machinery | Show hidden damage |

Inspecting wiring | Help you see loose or broken wires |

Reading gauges | Make numbers and dials easy to read |

You need the right flashlight for each job. Penlights are good for small spaces. LED flashlights give bright, steady light for bigger areas. Using the right flashlight helps you finish checks faster and make fewer mistakes.

Choosing a Flashlight

Task Requirements

You need to match your flashlight to your job. Every task on your maintenance tools list needs a different kind of light. If you work in dark spaces, you want ultra-bright headlamps. When you check tight spots, compact work lights help you see better. Multi-function lights give you options for many jobs. High CRI lights show colors clearly, which helps you spot problems. You should look for durability, power, adaptability, and long runtimes. These features make sure your flashlight works when you need it most.

Tip: Review your maintenance tools list before you buy a flashlight. This helps you pick the right tool for each job.

Feature | Description |

|---|---|

Brightness | Lets you see in dark places and keeps you safe. |

Durability | Stands up to tough work and does not break easily. |

Versatility | Works for many jobs on your maintenance tools list. |

User-friendly controls | Makes it easy to change settings fast. |

Rechargeable | Saves money and helps the planet. |

Color-Rite Technology | Shows colors well and keeps your eyes comfortable. |

Environmental Factors

Your work environment changes every day. You need to think about dust, water, and chemicals when you choose a flashlight for your maintenance tools list. Dust can get inside flashlights and block the light. Water can cause rust or make the flashlight stop working. Some dust can even catch fire, so you need a safe flashlight. Pick a model that fights dust and water. Look for flashlights with sealed bodies and safety ratings.

Dust exposure can block light and cause problems.

Water exposure can lead to rust and shorts.

Combustible dust can cause explosions.

Note: Always check your maintenance tools list for jobs in risky places. Choose flashlights that match those needs.

Comparing Models

You have many choices when you look at flashlights for your maintenance tools list. Some brands work better for certain jobs. Streamlight and SureFire make heavy-duty models for tough work. Olight and JetBeam offer lightweight options for outdoor jobs. Imalent and Armytek build ultra-bright flashlights for search and rescue. RovyVon and AceBeam design compact lights for daily use. You should compare features like brightness, battery life, and durability.

Use Case | Recommended Brands | Key Features |

|---|---|---|

Outdoor Enthusiasts | Olight, JetBeam | Lightweight, high-lumen, rugged durability |

Industrial & Professional Use | Streamlight, SureFire | Heavy-duty, reliable, extensive warranties |

Search & Rescue Teams | Imalent, Armytek | Ultra-bright, long-lasting, extreme conditions |

Everyday Carry | RovyVon, AceBeam | Compact, versatile designs for daily tasks |

Callout: Compare models on your maintenance tools list to find the best fit for each job.

Budget

You want to save money, but you also need good tools. If you pick cheap flashlights for your maintenance tools list, you may spend more later. Old lights use more energy and break faster. You will need to replace them often, which costs more in the long run. Rechargeable flashlights cost more at first, but they save you money over time. They also help you avoid buying new batteries all the time.

Budget choices can lead to higher costs later.

Outdated lights use more energy and need more repairs.

Rechargeable models help you save money and work better.

Tip: Check your maintenance tools list and invest in quality flashlights. This keeps your team safe and saves money.

Helius Flashlight and Essential Maintenance Tools

Product Overview

You need a reliable tool for your daily repairs. The helius flashlight gives you strong light in dark places. You can use it for quick checks or long repairs. This tool stands out among essential maintenance tools because it works in tough conditions. The body resists drops and water. You get a bright beam that helps you see every detail during repairs. The helius flashlight uses rechargeable batteries, so you save money and keep working longer. You can switch between lighting modes for different repairs. The design fits in your hand, pocket, or tool belt. You can trust this tool for all your essential maintenance tools needs.

Tip: Choose the helius flashlight when you want a tool that lasts through many repairs.

Feature | Benefit for Repairs |

|---|---|

Bright LED Beam | Helps you spot problems |

Rechargeable | Keeps you ready for repairs |

Durable Body | Survives drops and spills |

Compact Design | Easy to carry for repairs |

Integration in Daily Workflows

You use the helius flashlight every day for repairs. You grab it before you start your shift. You check machines, wires, and pipes with clear light. The helius flashlight helps you finish repairs faster. You can clip it to your belt or use the magnetic base for hands-free repairs. You work in small spaces and need both hands for repairs. The helius flashlight gives you light without getting in your way. You add it to your list of essential maintenance tools because it helps with every repair job. You use it for emergency repairs, routine checks, and inspections. You train your team to use the helius flashlight for safe repairs. You keep it charged and ready for all repairs.

You save time on repairs with quick access to light.

You avoid mistakes during repairs by seeing every part clearly.

You improve safety for your team during repairs.

Note: The helius flashlight makes repairs easier and safer. Add it to your essential maintenance tools for better results.

Industrial flashlights help you stay safe and work faster during routine maintenance. You choose the right flashlight for each job and environment. You keep your flashlight ready and use it every day. You check your lighting needs often and learn about new technology. You make your team safer and more efficient with good lighting.

Tip: Add flashlight checks to your daily routine for better results.

FAQ

What tools should every maintenance technician carry for industrial operations?

You should carry flashlights, screwdrivers, pliers, and wrenches. These tools help you fix machines and check equipment. Maintenance technicians also use PPE like gloves and safety glasses. Good tools help you stay safe and work faster in factories.

How do flashlights help a maintenance team during inspections?

Flashlights help you see in dark places. You can find leaks, cracks, or broken wires with bright light. Your team uses flashlights to spot problems early. You finish inspections faster and make fewer mistakes. Flashlights are important for every maintenance technician.

Why is PPE important for a technician using tools in industrial operations?

PPE keeps you safe from harm. You wear gloves, helmets, and safety glasses when you use tools. PPE protects you from sharp edges, heat, and chemicals. Every technician needs personal protective equipment in industrial operations.

How do you choose the best tools for your maintenance technician role?

Think about your daily jobs. Pick tools that match your tasks. Choose strong flashlights, sturdy wrenches, and reliable testers. Your role needs tools that last a long time. Ask your team for advice on the best tools for each job.

Can you use regular flashlights as tools for industrial operations?

Regular flashlights may not work well in tough places. You need flashlights made for industrial operations. Pick ones that resist water, dust, and drops. Maintenance technicians use special tools to stay safe and work faster.

See Also

Exploring UV Flashlights: Uses And Advantages Explained

Key Guidelines For Proper Flashlight Care And Upkeep

Must-Have Headlamps For Convenient Hands-Free Lighting