How Flashlight Materials Influence Weight and Portability

The material of a flashlight plays a major role in its weight and portability. When you choose a flashlight, understanding its material properties helps you make a better decision. For example, tensile strength shows how much stress a material can handle before breaking, which impacts durability. Thermal conductivity determines how well a material handles heat. Plastic polymers, for instance, conduct heat slowly, making them safer to touch in high-temperature situations. On the other hand, metal flashlights conduct electricity better, which can be risky in electrical environments. By exploring different flashlight materials, you can find the right balance between safety, durability, and ease of use.

Key Takeaways

Flashlight materials affect how heavy and easy to carry they are. Pick aluminum for a light and portable choice.

Aluminum and titanium are great for outdoor activities. They are strong and light, perfect for hiking or camping trips.

Plastic flashlights are super light but not very strong. They are good for simple tasks or as backups in emergencies.

Stainless steel is very tough and strong. It works well for tough jobs but is heavier, making it less portable.

Think about what you need before picking a flashlight. Check the weight, strength, and how you will use it to choose the best one.

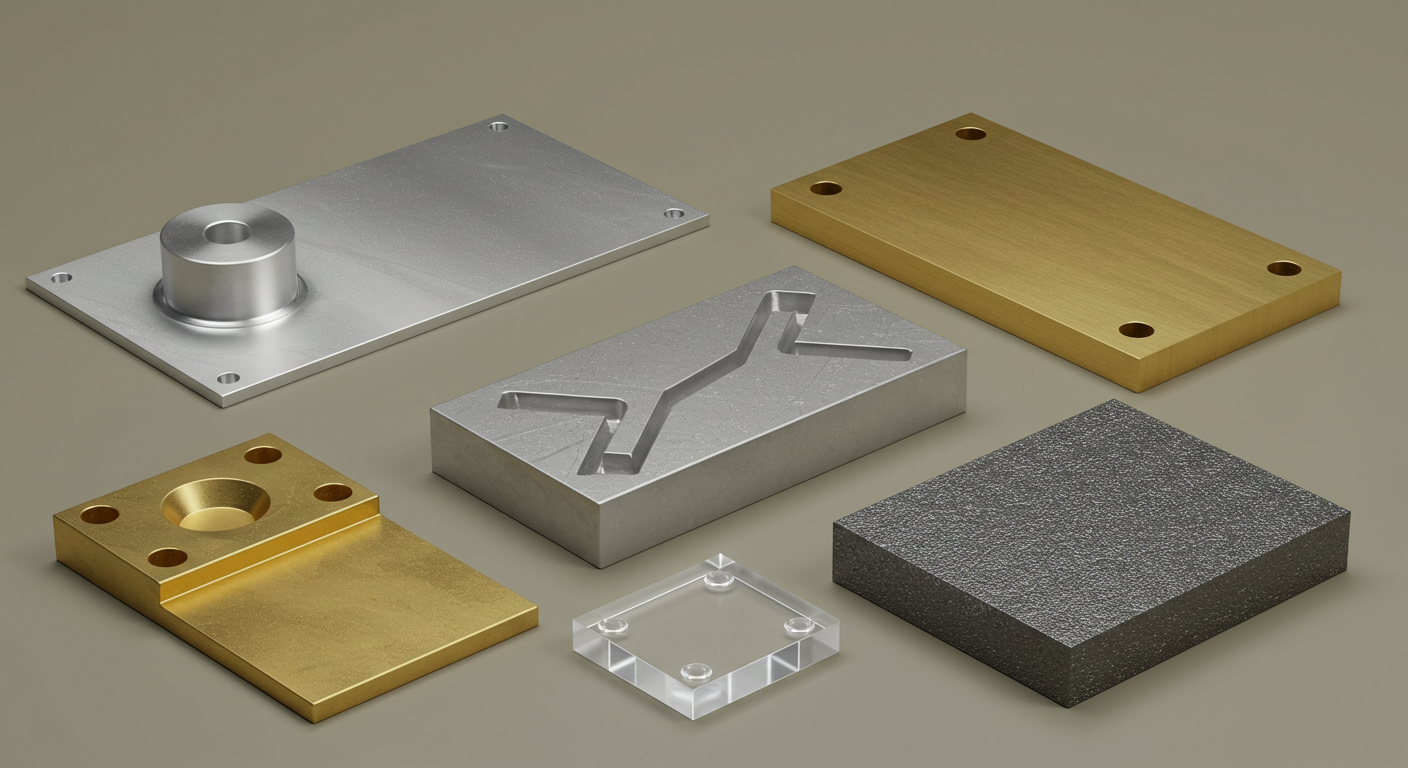

Overview of Different Flashlight Materials

Aluminum

Characteristics and benefits of aluminum

Aluminum stands out as one of the most popular materials for flashlights due to its lightweight and durable nature. It offers excellent heat conduction, which helps prevent overheating during extended use. Manufacturers often anodize aluminum to enhance its resistance to wear and corrosion. Type III anodizing, in particular, provides a thicker, more durable coating that increases longevity and allows for various color options. Additionally, aluminum flashlights often feature non-conductive areas to ensure safe and efficient functionality.

Common applications for aluminum flashlights

You’ll find aluminum flashlights widely used in outdoor activities like hiking and camping. Their lightweight design makes them easy to carry, while their durability ensures they can withstand rough conditions. Aluminum is also a cost-effective choice, making it suitable for everyday carry (EDC) flashlights and emergency kits.

Titanium

Key features and advantages of titanium

Titanium is known for its exceptional strength-to-weight ratio. It is about 45% lighter than stainless steel, yet it offers superior durability and corrosion resistance. This makes titanium flashlights highly reliable, even in extreme environments. While heavier than aluminum, titanium provides unmatched toughness, making it a favorite among those who prioritize durability over weight.

Popularity among premium flashlight users

Titanium flashlights appeal to premium users, including outdoor enthusiasts and professionals. Their sleek design and long-lasting performance justify their higher price point. If you value a flashlight that can handle rugged use while maintaining a lightweight feel, titanium is an excellent choice.

Plastic

Types of plastics used in flashlights (e.g., ABS, polycarbonate)

Plastic flashlights often use materials like Acrylonitrile Butadiene Styrene (ABS) and polycarbonate. ABS offers moderate weight and exceptional durability, making it resistant to chemicals and impacts. Polycarbonate, on the other hand, is lightweight and highly resistant to shattering, making it ideal for flashlights that need to endure drops or rough handling.

Pros and cons of plastic flashlights

Plastic flashlights are ultra-lightweight, which makes them easy to carry for long periods. They are also less prone to scratching and warping compared to metal flashlights. However, they may lack the durability of aluminum or titanium, especially in extreme conditions. Plastic flashlights are best suited for casual use or as backup options in emergency kits.

Stainless Steel

Durability and corrosion resistance of stainless steel

Stainless steel flashlights are known for their exceptional durability and resistance to corrosion. This material withstands wear and tear, making it ideal for long-term use. Its ability to resist scratches and dents ensures that your flashlight maintains a polished appearance even after years of use. The table below highlights the key advantages of stainless steel in terms of durability and corrosion resistance:

Advantage | Description |

|---|---|

High Durability | Stainless steel resists wear and tear, ensuring a longer lifespan for flashlights. |

Resistance to Wear | The material's resistance to scratches and dents keeps the flashlight looking new over time. |

Use cases for stainless steel flashlights

You might find stainless steel flashlights particularly useful in professional settings. Their robust construction makes them suitable for industrial environments, where tools often face harsh conditions. These flashlights also perform well in marine or coastal areas, as their corrosion resistance protects them from saltwater exposure. While heavier than other options, stainless steel flashlights offer unmatched reliability for users who prioritize toughness over portability.

Other Materials

Overview of copper, magnesium alloy, and carbon fiber

Some flashlights use materials like copper, magnesium alloy, and carbon fiber to meet specific needs. Each material offers unique properties that cater to niche applications:

Magnesium Alloy: Lightweight and durable, this material provides excellent heat dissipation. It works well for outdoor activities where portability and performance are essential.

Copper: Known for its superior thermal conductivity, copper flashlights efficiently manage heat. They resist corrosion, possess antimicrobial properties, and develop a distinctive patina over time, adding aesthetic appeal.

Carbon Fiber: This material boasts a high strength-to-weight ratio, making it stronger than aluminum and titanium. It resists corrosion and withstands extreme temperatures, making it ideal for demanding environments.

Niche applications and unique benefits of these materials

Flashlights made from these materials often serve specialized purposes. Magnesium alloy flashlights are perfect for hikers and campers who need lightweight gear. Copper flashlights appeal to collectors and those who value antimicrobial properties, such as healthcare professionals. Carbon fiber flashlights suit extreme conditions, including high-temperature industrial settings or outdoor expeditions. These options demonstrate how different flashlight materials can address specific user requirements.

Material-Specific Analysis of Weight and Portability

Aluminum

Lightweight yet durable properties of aluminum

Aluminum flashlights strike a balance between weight and strength. This material is lightweight, making it easy for you to carry during long hikes or daily commutes. Despite its lightness, aluminum remains durable enough to handle accidental drops or rough handling. Its natural resistance to corrosion ensures that your flashlight stays functional even in wet or humid conditions. Manufacturers often anodize aluminum to enhance its durability further, giving you a reliable tool for various situations.

Portability considerations for aluminum flashlights

The portability of aluminum flashlights makes them a favorite for outdoor enthusiasts and everyday users. Their lightweight design reduces fatigue when you carry them for extended periods. You can easily slip one into your backpack or pocket without adding unnecessary bulk. Aluminum’s durability also means you won’t need to worry about frequent replacements, making it a practical choice for those who value convenience and reliability.

Titanium

Weight-to-strength ratio of titanium

Titanium offers an impressive weight-to-strength ratio. It is significantly lighter than stainless steel while maintaining exceptional durability. This makes titanium flashlights resistant to impacts and wear, ensuring they last through demanding conditions. You’ll find titanium flashlights ideal for situations where both strength and portability are essential.

Trade-offs between portability and cost

While titanium flashlights excel in portability, their high cost may give you pause. The rarity of titanium and the complexity of its manufacturing process contribute to its premium price. However, the benefits include:

Durability: Titanium resists impact and wear, ensuring long-term reliability.

Lightweight: It is about 45% lighter than stainless steel, making it easier to carry.

Cost: The higher price reflects its superior quality and performance.

If you’re willing to invest in a durable and lightweight flashlight, titanium offers excellent value despite its cost.

Plastic

Ultra-lightweight nature of plastic flashlights

Plastic flashlights are among the lightest options available. Materials like ABS and polycarbonate reduce weight significantly, making these flashlights easy for you to carry. Their lightweight nature makes them ideal for children, casual users, or anyone who prioritizes portability over durability.

Portability benefits and durability limitations

The portability of plastic flashlights is unmatched. You can carry them effortlessly in your bag or pocket without feeling weighed down. However, their durability may not match that of aluminum or titanium. Plastic flashlights are more prone to cracking or breaking under extreme conditions. They work best as backup options or for light-duty tasks where weight is a primary concern.

Stainless Steel

Heavier weight but superior durability

Stainless steel flashlights are heavier than those made from aluminum or plastic. This weight comes from the material's dense structure, which contributes to its exceptional durability. You can rely on stainless steel to resist impacts, scratches, and corrosion. This makes it a great choice for environments where tools face constant wear and tear. The added weight also gives these flashlights a solid feel in your hand, which some users prefer for professional or industrial applications.

Stainless steel's durability ensures that your flashlight will last for years, even with frequent use. It can handle extreme conditions, including exposure to moisture or chemicals. If you prioritize toughness and longevity, stainless steel is a dependable option. However, the weight might not suit everyone, especially if you need a flashlight for extended outdoor activities.

Portability challenges for stainless steel flashlights

The weight of stainless steel flashlights can pose challenges when portability is a priority. Carrying one for long periods may cause fatigue, especially during hiking or camping trips. These flashlights are also bulkier, which can make them less convenient to pack in small bags or pockets.

Despite these drawbacks, stainless steel flashlights excel in situations where durability outweighs portability. For example, they are ideal for industrial workers or emergency responders who need reliable tools in harsh conditions. If you value portability, you might want to explore lighter materials like aluminum or plastic.

Other Materials

Weight and portability of copper, magnesium alloy, and carbon fiber

Flashlights made from copper, magnesium alloy, and carbon fiber offer unique advantages in terms of weight and portability. Copper flashlights are heavier than aluminum but lighter than stainless steel. Magnesium alloy provides a lightweight alternative with excellent strength. Carbon fiber stands out as the lightest option, offering superior portability without compromising durability.

Each material has distinct characteristics that affect its usability. Copper flashlights feel solid and durable, but their weight might limit portability. Magnesium alloy strikes a balance between weight and strength, making it suitable for outdoor enthusiasts. Carbon fiber flashlights are incredibly light, allowing you to carry them effortlessly during long trips.

Specialized use cases for these materials

These materials cater to specific needs and preferences. Copper flashlights are popular among collectors due to their unique patina and antimicrobial properties. Magnesium alloy flashlights are perfect for hikers and campers who need lightweight yet durable gear. Carbon fiber flashlights excel in extreme environments, such as high-temperature industrial settings or challenging outdoor expeditions.

When choosing a flashlight, consider how these materials align with your priorities. Whether you need lightweight portability, durability, or aesthetic appeal, these options demonstrate the versatility of different flashlight materials.

Practical Implications for Users

Outdoor Enthusiasts

Best materials for hiking, camping, and rugged outdoor use

When you venture into the outdoors, your flashlight must handle tough conditions while remaining easy to carry. Materials like aluminum, magnesium alloy, and titanium stand out for their balance of durability and portability. Here’s why these materials are ideal:

Aluminum: Lightweight and corrosion-resistant, aluminum flashlights are perfect for long hikes. They can withstand drops and rough handling without adding unnecessary weight to your gear.

Magnesium Alloy: Even lighter than aluminum, magnesium alloy offers excellent strength and heat dissipation. This makes it a great choice for camping trips where you need reliable performance.

Titanium: Known for its exceptional strength-to-weight ratio, titanium flashlights endure rugged use while remaining portable. They are slightly heavier than aluminum but offer unmatched durability.

Choosing a flashlight made from these materials ensures you’re prepared for any outdoor challenge, whether it’s navigating trails or setting up camp in the dark.

Emergency Use

Recommended materials for flashlights in emergency kits

In emergencies, you need a flashlight that performs reliably under stress. Materials like aluminum, stainless steel, and ABS plastic are highly recommended for their durability and resilience. Consider these features when selecting a flashlight for your emergency kit:

Aluminum: Its lightweight nature and corrosion resistance make it a dependable option for emergencies.

Stainless Steel: Heavier but incredibly robust, stainless steel flashlights withstand impacts and harsh conditions.

ABS Plastic: While not as durable as metals, ABS plastic is lightweight and resistant to chemicals, making it a practical backup option.

Look for flashlights with water resistance, shock resistance, and sturdy construction. These features ensure your flashlight remains functional during power outages, storms, or other crises.

Everyday Carry (EDC)

Lightweight and portable options for daily use

For daily use, you need a flashlight that’s easy to carry and fits seamlessly into your routine. Lightweight materials like magnesium alloy, titanium, and carbon fiber excel in this category. The table below highlights their key properties:

Material | Weight | Durability | Corrosion Resistance | Heat Dissipation |

|---|---|---|---|---|

Magnesium Alloy | Very Low | High | Moderate | Excellent |

Titanium | Low | Very High | High | Moderate |

Carbon Fiber | Very Low | High | High | Low |

Magnesium alloy and carbon fiber flashlights are ideal if you prioritize portability. Titanium offers a slightly heavier option but provides superior durability for everyday tasks. These materials ensure your flashlight remains convenient to carry while delivering reliable performance whenever you need it.

Professional Use

Materials suited for law enforcement, military, and industrial applications

When you work in demanding environments, your flashlight must meet high standards for durability and performance. Professionals like law enforcement officers, military personnel, and industrial workers rely on flashlights that can handle extreme conditions. Choosing the right material ensures your flashlight performs reliably when you need it most.

Here are the top materials suited for professional use:

Stainless Steel: This material offers unmatched durability. It resists impacts, scratches, and corrosion, making it ideal for industrial settings. If you work in environments with chemicals or moisture, stainless steel ensures your flashlight stays functional. Its weight provides a solid grip, which is useful during tactical operations.

Titanium: Known for its strength-to-weight ratio, titanium flashlights are perfect for military and law enforcement use. They withstand rough handling and extreme conditions while remaining lightweight. Titanium also resists corrosion, ensuring long-term reliability in harsh environments.

Aluminum: Lightweight yet durable, aluminum flashlights are a practical choice for professionals. Anodized aluminum resists wear and corrosion, making it suitable for outdoor and industrial applications. Its lighter weight reduces fatigue during extended use.

Tip: For tactical operations, consider flashlights with stainless steel or titanium. These materials provide the durability and reliability you need in high-pressure situations.

Material | Durability | Weight | Corrosion Resistance | Ideal Use Case |

|---|---|---|---|---|

Stainless Steel | Very High | Heavy | High | Industrial and tactical use |

Titanium | High | Moderate | Very High | Military and law enforcement |

Aluminum | Moderate | Light | High | Outdoor and industrial tasks |

Each material offers unique advantages. Stainless steel excels in toughness, titanium balances strength and weight, and aluminum provides lightweight portability. By understanding these options, you can select a flashlight that meets your professional needs.

Tips for Choosing the Right Material Based on Needs

Assessing Your Primary Use Case

Questions to determine the best material for your needs

Choosing the right flashlight material starts with understanding your primary use case. Ask yourself these questions to narrow down your options:

What is the flashlight's purpose? Will it be for everyday carry (EDC), emergencies, outdoor adventures, or professional use?

How important is quality and reliability for your needs?

What type of battery does the flashlight require?

Do you prefer a specific light tint or brightness level?

Is the user interface simple and intuitive?

Does the flashlight offer flat regulation for consistent brightness?

What is your budget?

What form factor suits your preferences?

How many lumens do you need for your tasks?

Answering these questions helps you identify the material that aligns with your priorities. For example, aluminum suits outdoor enthusiasts due to its lightweight and durable nature, while stainless steel works well for industrial applications requiring toughness.

Balancing Weight, Portability, and Durability

How to prioritize features based on intended use

Balancing weight, portability, and durability depends on your specific needs. The table below highlights how different materials perform in these areas:

Material | Durability | Weight Consideration | Cost-Effectiveness |

|---|---|---|---|

Stainless Steel | Long-lasting, impact-resistant | Heavier than titanium and polymers | Moderate cost |

Titanium | Exceptional strength-to-weight ratio | 40% less dense than stainless steel | Higher cost, premium option |

Polymers (Plastic) | Versatile, adaptable to environments | Lightweight, budget-friendly options | Cost-effective, especially recycled plastics |

If you prioritize portability, polymers or titanium are excellent choices. For maximum durability, stainless steel offers unmatched toughness. Consider how much weight you are willing to carry and the conditions your flashlight will face.

Budget Considerations

How material choice impacts cost and long-term value

Your budget plays a significant role in selecting the right flashlight material. Aluminum alloys provide a balance of affordability and durability, making them a great long-term investment. Plastic polymers like ABS are cost-effective and lightweight, but they may not hold up under extreme conditions. If you’re looking for premium quality, titanium offers exceptional performance but comes at a higher price.

Tip: Investing in a durable material like aluminum or titanium can save you money in the long run by reducing the need for replacements.

Flashlight materials directly impact their weight, portability, and usability. Aluminum offers durability and lightness, while stainless steel provides unmatched toughness at the cost of added weight. For specific needs, consider these tips:

Choose waterproof flashlights for fishing.

Use red-light models for hunting to avoid disturbing wildlife.

Opt for lightweight, high-visibility designs for running.

Select compact, adjustable-brightness flashlights for geocaching.

Balancing practicality, budget, and personal preferences ensures you find the perfect flashlight. By understanding material properties, you can confidently select a flashlight that meets your unique requirements.

FAQ

What is the lightest material for flashlights?

Plastic, especially ABS or polycarbonate, is the lightest material used in flashlights. It’s ideal for casual use or as a backup option. If you need something lightweight but more durable, magnesium alloy or carbon fiber offers a great balance of portability and strength.

Are heavier flashlights more durable?

Not always. While materials like stainless steel are heavier and highly durable, lightweight options like titanium and carbon fiber also provide excellent strength. Durability depends on the material's properties, not just its weight. Choose based on your specific needs, such as ruggedness or portability.

Which material is best for outdoor activities?

Aluminum and magnesium alloy are top choices for outdoor use. Both materials are lightweight, durable, and resistant to corrosion. Titanium is another excellent option if you need extra toughness for extreme conditions, though it’s slightly heavier than aluminum.

Do plastic flashlights break easily?

Plastic flashlights, especially those made from polycarbonate, are surprisingly durable. They resist impacts and shattering but may not perform well under extreme conditions like high heat or heavy pressure. For casual or emergency use, plastic flashlights are reliable and affordable.

Why are titanium flashlights so expensive?

Titanium’s high cost comes from its rarity and the complexity of its manufacturing process. It offers exceptional strength, corrosion resistance, and a lightweight design. These qualities make titanium flashlights a premium option for users who prioritize durability and performance over cost.

See Also

Explore Various Categories of Flashlights Available Today

What Is the Visibility Range of Rechargeable Flashlights?

Key Guidelines for Proper Flashlight Care and Upkeep

Comparing Diving Flashlights to Standard Flashlights: Key Differences

Maximize Your Flashlight Battery Life with These Helpful Tips