5 Essential Materials for Flashlight Housing Explained

Selecting the appropriate materials for flashlight housing is a critical decision that impacts durability and performance. This blog provides an insightful exploration of five essential materials commonly used in flashlight construction. By understanding the unique properties of each material, readers can make informed choices when selecting flashlights for various applications.

Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile Butadiene Styrene (ABS) is a versatile material known for its exceptional durability and chemical resistance. Its robust nature makes it an ideal choice for various applications in flashlight housing.

Properties of ABS

Durability: ABS exhibits remarkable strength, ensuring the longevity of flashlight housings even in demanding conditions.

Chemical resistance: The material's resistance to corrosive substances enhances the lifespan of flashlights, making them suitable for diverse environments.

Uses in Flashlight Housing

Common applications: ABS is widely used in manufacturing plastic polymer flashlights due to its ability to withstand high temperatures without compromising safety.

Advantages: Flashlights constructed with ABS are safer to handle and offer better protection for batteries, especially in extreme heat scenarios.

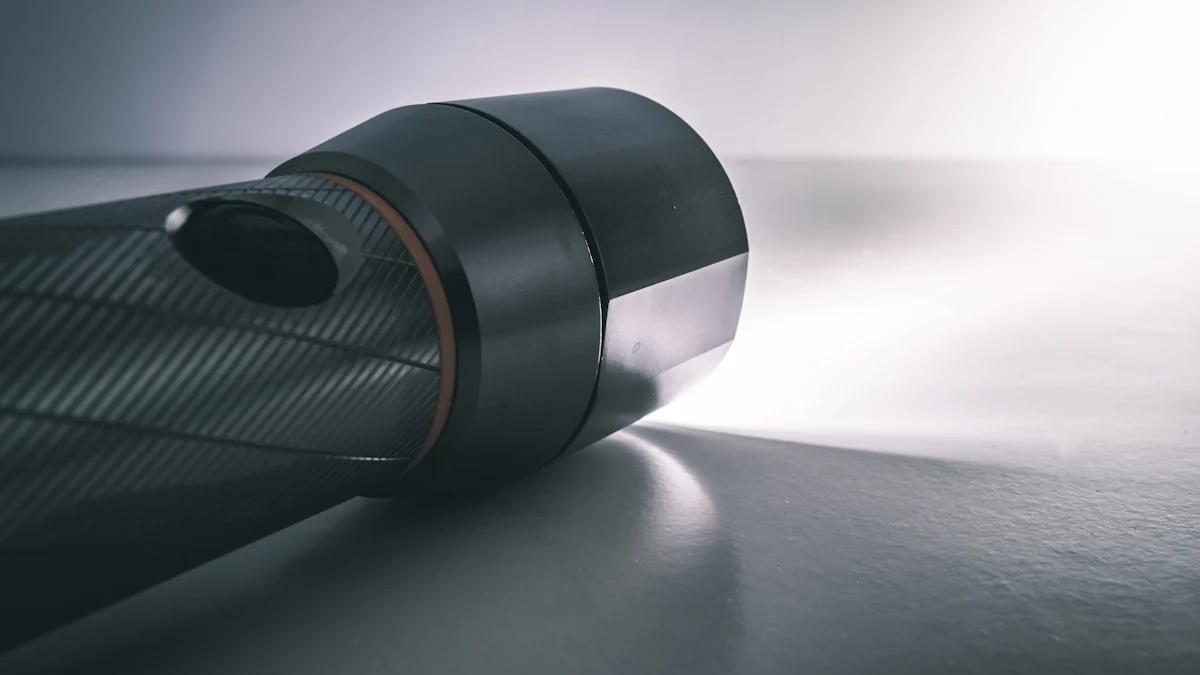

Aluminum Alloy

Properties of Aluminum Alloy

Lightweight

Aluminum alloy stands out for its remarkable lightweight nature, a crucial factor in flashlight manufacturing. This characteristic ensures that flashlights remain portable and easy to carry, making them ideal for various outdoor activities and emergency situations.

Heat conduction

One of the key advantages of aluminum alloy in flashlight housing is its exceptional heat conduction properties. This feature allows the flashlight to dissipate heat effectively, preventing overheating issues during prolonged use. Additionally, the material's ability to conduct heat efficiently contributes to the overall longevity and performance of the flashlight.

Uses in Flashlight Housing

High-quality flashlights

Manufacturers often opt for aluminum alloy when crafting high-quality flashlights due to its superior strength and durability. These flashlights are designed to withstand rugged conditions and provide reliable illumination in challenging environments, making them a popular choice among outdoor enthusiasts and professionals.

Heat dissipation

The use of aluminum alloy in flashlight housing serves a dual purpose by not only enhancing the structural integrity but also improving heat dissipation. This ensures that the internal components of the flashlight remain cool during operation, prolonging their lifespan and maintaining optimal performance levels.

Stainless Steel

Properties of Stainless Steel

Strength

Stainless steel boasts exceptional strength, ensuring the reliability and robustness of flashlight housings in various conditions. This material's high tensile strength makes it a preferred choice for flashlights that need to withstand rough handling and challenging environments.

Corrosion resistance

The corrosion-resistant nature of stainless steel is a key feature that enhances the longevity of flashlight housings. By resisting rust and oxidation, stainless steel ensures that the flashlight remains durable even when exposed to moisture or harsh outdoor elements.

Uses in Flashlight Housing

Durability

Utilizing stainless steel in flashlight housing guarantees long-lasting durability, making it an ideal choice for heavy-duty applications. Flashlights constructed with stainless steel are known for their ability to endure impacts and maintain structural integrity over extended periods.

Aesthetic appeal

In addition to its durability, stainless steel provides a sleek and professional appearance to flashlight housings. The polished finish of stainless steel not only enhances the visual appeal of the flashlight but also conveys a sense of quality and craftsmanship to users.

Titanium

Titanium, known for its exceptional strength-to-weight ratio and corrosion resistance, is a premium choice for flashlight housing. Compared to stainless steel and aluminum alloy, titanium offers unique advantages that cater to specific needs.

Properties of Titanium

Strength-to-weight ratio

Titanium surpasses stainless steel in strength while being 40% less dense, providing durability without adding unnecessary weight.

The material's high strength ensures the longevity of flashlights in demanding environments, making it a reliable option for outdoor enthusiasts and professionals alike.

Corrosion resistance

Titanium's superior resistance to corrosion outshines stainless steel, ensuring that flashlight housings remain intact even in harsh conditions.

This feature makes titanium flashlights ideal for prolonged use in challenging environments where exposure to moisture or corrosive elements is common.

Uses in Flashlight Housing

Premium flashlights

Manufacturers opt for titanium when crafting premium flashlights due to its exceptional properties that guarantee reliability and longevity.

Titanium flashlights are designed to withstand rough handling and extreme conditions, making them a top choice for users who prioritize quality and performance.

Longevity

Flashlights constructed with titanium offer unparalleled longevity, ensuring that they remain functional over extended periods of use.

The material's durability and resistance to wear make titanium flashlights a valuable investment for those seeking long-lasting illumination solutions.

Polymers (e.g., Polystyrene)

Properties of Polymers

Versatility

Plastic polymer flashlights offer remarkable versatility in various environments. Their adaptability to extreme temperatures ensures consistent performance, making them a reliable choice for diverse lighting needs. The ability of polymers to withstand high heat levels without quick conductivity safeguards users and batteries from excessive heat exposure.

Cost-effectiveness

Manufacturers are increasingly embracing sustainable practices by incorporating cost-effective materials like recycled plastics in flashlight production. This eco-friendly approach not only reduces the ecological footprint but also enhances the affordability of flashlights for consumers. By utilizing recycled polymers, flashlight makers create budget-friendly options without compromising on quality or durability.

Uses in Flashlight Housing

Budget-friendly options

The integration of recycled plastics in flashlight housing presents budget-friendly solutions for consumers seeking reliable illumination tools. These affordable options cater to a wide range of users, offering cost-effective alternatives without sacrificing performance or durability.

Customizability

Plastic polymer flashlights provide a platform for customization, allowing manufacturers to create unique designs tailored to specific user preferences. The flexibility of polymers enables intricate detailing and personalized features, enhancing the aesthetic appeal and functionality of flashlights for different applications.

Manufacturers are increasingly incorporating renewable and environmentally friendly materials to reduce the ecological footprint of flashlights.

Flashlight makers are contributing to the creation of eco-friendly lighting solutions, aligning with the industry's sustainable practices.

The future of flashlights is promising, with advancements in smart features, battery efficiency, and sustainable materials enhancing their functionality.

Modern flashlights prioritize durability and waterproof construction, ensuring reliable performance in various environments.

LED technology continues to drive innovation in the flashlight market, offering brighter illumination and energy-efficient options for consumers.

2024/6/5

See Also

Top Tips for Selecting the Perfect EDC Flashlight

Key Pointers for Maintaining Your Flashlight

The Definitive Manual for Flashlight Care and Cleaning

Exploring Various Kinds of Flashlights

Mastering Flashlight Battery Essentials: Your Complete Guide