3 Ways Rapid Prototyping Boosts CNC Parts

Rapid Prototyping has revolutionized the approach to manufacturing by enabling the swift creation and testing of designs, thereby minimizing failure risks and accelerating development. CNC Parts are integral to this process, providing the precision and reliability crucial for industries focused on high-quality production. The synergy between Rapid Prototyping and CNC Parts machining boosts efficiency and fosters innovation. This combination not only streamlines design iterations but also meets the increasing demand for customized solutions. As the CNC machining market trends positively, adopting these technologies is essential for maintaining competitiveness.

Enhancing Design Flexibility with Rapid Prototyping

Rapid Iteration and Testing in CNC Parts

Shortening the Design Cycle

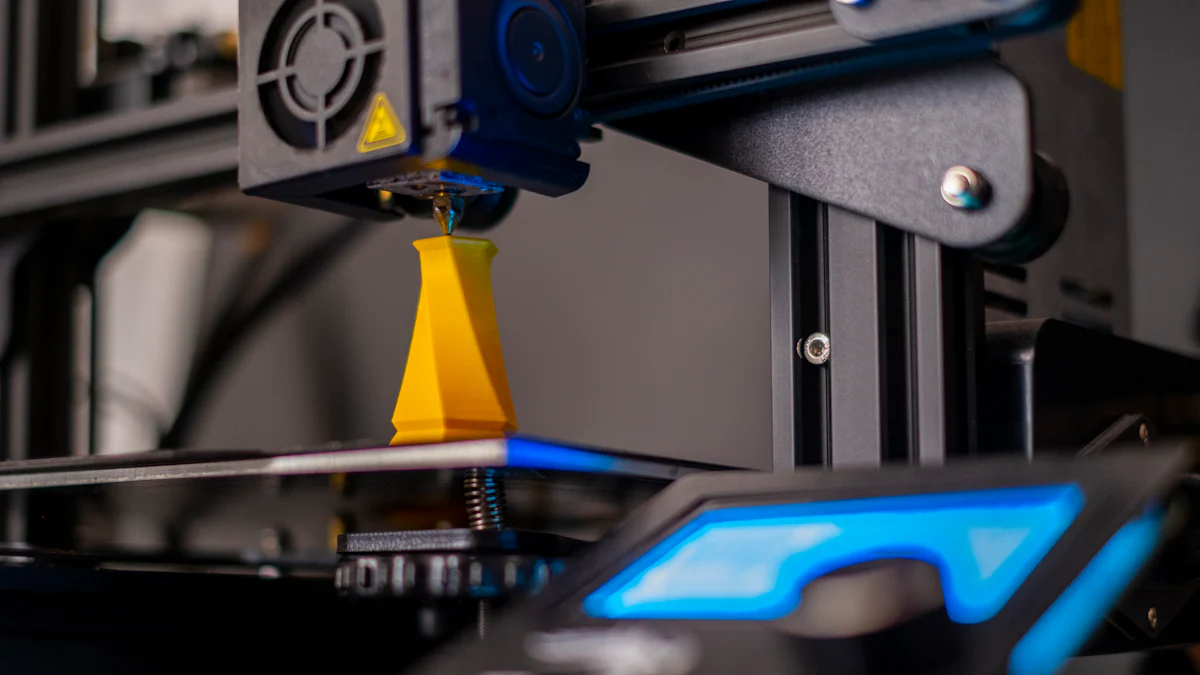

Rapid Prototyping empowers you to quickly iterate on designs, significantly reducing the time it takes to move from concept to production. By using this approach, you can create multiple versions of CNC Parts in a short period. This process allows you to test and refine designs without the lengthy delays typical of traditional methods. The ability to rapidly produce prototypes means you can identify and address potential issues early, ensuring that the final product meets your expectations.

Facilitating Creative Solutions

When you embrace Rapid Prototyping, you open the door to innovative solutions. The flexibility to experiment with different designs and materials encourages creativity. You can explore unconventional ideas and push the boundaries of what is possible with CNC Parts. This freedom leads to unique and effective solutions that might not have been considered otherwise. By fostering an environment where creativity thrives, you enhance the overall quality and functionality of your products.

Customization and Personalization of CNC Parts

Meeting Specific Client Needs

In today's market, customization is key. Rapid Prototyping allows you to tailor CNC Parts to meet the specific needs of your clients. Whether it's adjusting dimensions, altering materials, or incorporating unique features, you can provide personalized solutions that align with client requirements. This level of customization not only satisfies clients but also strengthens your competitive edge in the industry.

Adapting to Market Trends

Staying ahead of market trends is crucial for success. With Rapid Prototyping, you can quickly adapt your CNC Parts to reflect the latest developments in your industry. This adaptability ensures that your products remain relevant and appealing to consumers. By keeping pace with changing trends, you position yourself as a leader in innovation and responsiveness.

Improving Production Efficiency through Rapid Prototyping

Reducing Lead Times for CNC Parts

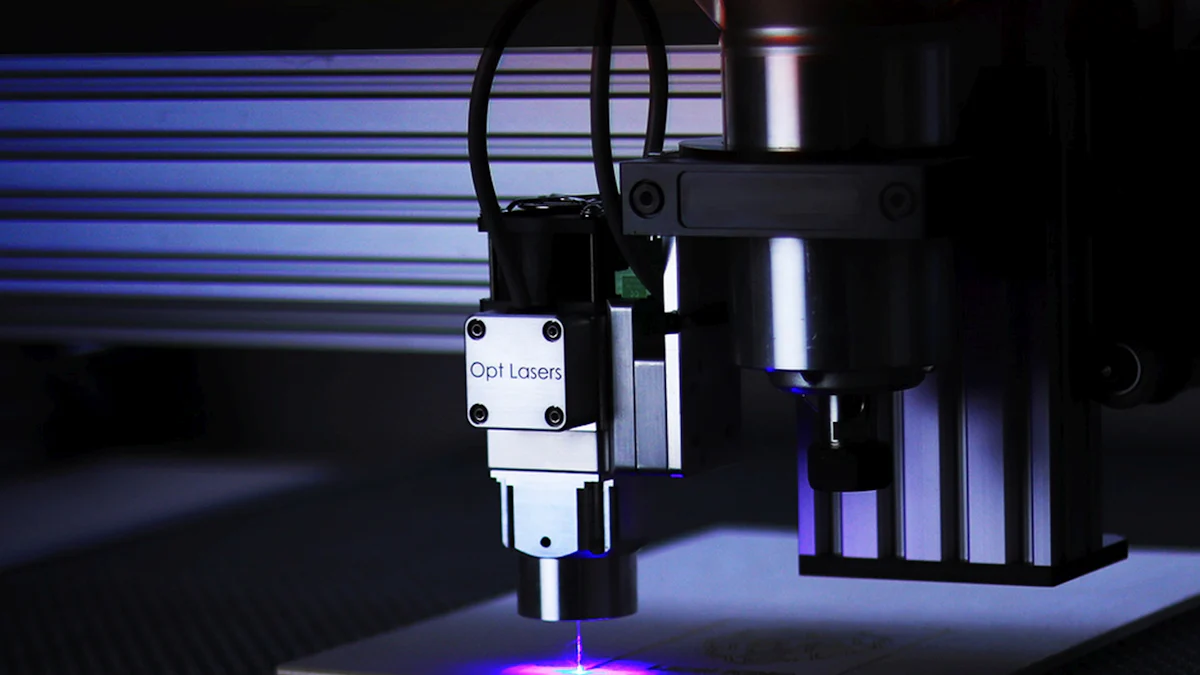

Accelerating Time-to-Market

You can significantly speed up your product's journey from concept to market by utilizing Rapid Prototyping. This approach allows you to quickly produce CNC Parts, which means you can respond faster to market demands. The ability to rapidly create prototypes ensures that you can test and refine your designs without unnecessary delays. As a result, you can launch your products sooner, giving you a competitive edge in the fast-paced manufacturing industry.

Streamlining Production Processes

Rapid Prototyping streamlines your production processes by simplifying complex tasks. You can efficiently manage the creation of CNC Parts, reducing the time and effort required for each production cycle. This efficiency not only saves you time but also reduces the likelihood of errors during manufacturing. By optimizing your production processes, you can focus on delivering high-quality products consistently.

Minimizing Material Waste in CNC Parts Production

Cost-Effective Manufacturing

When you adopt Rapid Prototyping, you can achieve cost-effective manufacturing. This method allows you to use materials more efficiently, minimizing waste during the production of CNC Parts. By reducing material waste, you lower your production costs, which can lead to increased profitability. Efficient use of resources ensures that you can maintain competitive pricing while delivering quality products.

Sustainable Production Practices

Embracing sustainable production practices is crucial in today's environmentally conscious world. Rapid Prototyping supports these practices by reducing material waste and promoting efficient use of resources. You can produce CNC Parts with minimal environmental impact, aligning your manufacturing processes with sustainability goals. By prioritizing eco-friendly practices, you contribute to a healthier planet while meeting consumer expectations for responsible production.

Enhancing Product Quality of CNC Parts

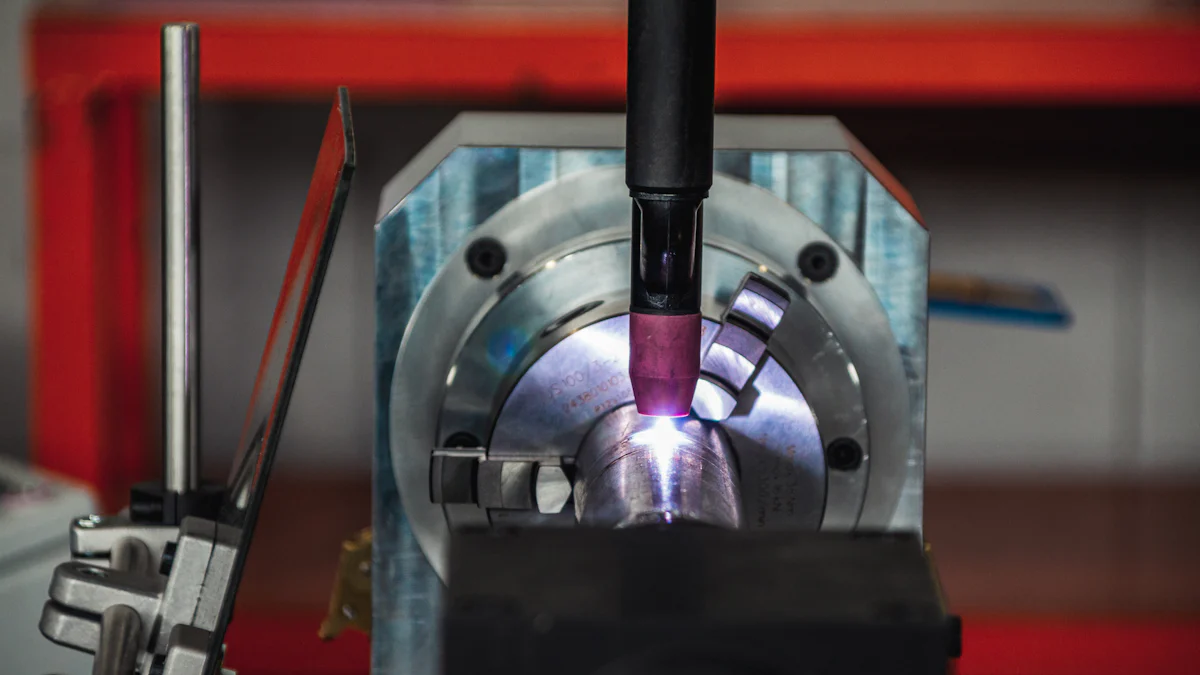

Precision and Accuracy in CNC Parts

Achieving High Tolerance Levels

You can achieve high tolerance levels in CNC Parts by utilizing Rapid Prototyping. This approach allows you to create parts with precise measurements, ensuring that each component fits perfectly within the assembly. High tolerance levels are crucial in industries where precision is paramount, such as aerospace and medical device manufacturing. By focusing on accuracy, you enhance the reliability and performance of your products.

Consistency in Production

Consistency in production is vital for maintaining quality standards. Rapid Prototyping helps you achieve this by enabling the replication of CNC Parts with uniform specifications. Each part produced matches the design specifications, reducing the risk of defects. Consistent production ensures that your products meet customer expectations and regulatory requirements, enhancing your reputation for quality.

Testing and Validation of CNC Parts

Ensuring Functionality and Durability

Testing and validation are essential steps in the production of CNC Parts. Rapid Prototyping allows you to test the functionality and durability of your designs before full-scale production. By creating prototypes, you can evaluate how parts perform under real-world conditions. This process helps you identify any weaknesses or potential failures, ensuring that the final product is robust and reliable.

Identifying and Correcting Flaws Early

Early identification and correction of flaws are critical to successful manufacturing. With Rapid Prototyping, you can detect issues in the design phase, allowing you to make necessary adjustments before mass production. This proactive approach saves time and resources by preventing costly errors. By addressing flaws early, you improve the overall quality of your CNC Parts and increase customer satisfaction.

Rapid Prototyping offers numerous advantages for CNC Parts, enhancing design flexibility, improving production efficiency, and boosting product quality. By adopting this innovative approach, you can expedite your product development process and reduce costs. The precision, speed, and quality inherent in Rapid Prototyping ensure that your projects meet high standards. As you explore these benefits, consider integrating Rapid Prototyping into your manufacturing processes. This step will not only keep you competitive but also open new avenues for innovation and customization. Embrace this technology to transform your manufacturing landscape.

See Also

Uncover the Cyansky P50R: An Ultra-Bright High-Performance Torch

Top 5 Tips for Selecting the Perfect EDC Torch

Flexible and Handy Emergency Gear: Manual Power Flashlights